Technologies

SAPI VARIO

Technology for gentle blasting under low pressure

SAPI VARIO technology is used for cleaning:

- buildings of natural stone

- buildings of brick

- landmarks and monuments

- structures of hard and soft wood

- fire damage

- and others

Advantages of SAPI VARIO technology:

- environmentally safe and gentle for the blasted surfaces

- works in a wide range of pressures from 0.1 to 10 bar

- cleans using dry, humid and wet process

- provides high performance at minimal costs with minimum granulate consumption rate due to optimized blasting nozzles and accessories

- allows to use of 3 different blasting techniques

The concept of SAPI VARIO nozzles makes it possible to use 3 different ways of blasting with a single base nozzle.

- vortex technique

- flat-fan technique

- Venturi technique

The advantage is the possibility to optimize cleaning process for different types of pollution that contributes to increase productivity rate and leads to better results. By replacing the required heads of the main nozzle it is possible to create a vortex, flat-fan or venturi-shaped jet.

Besides, for each of these types of jet there are manufactured nozzles in various sizes.

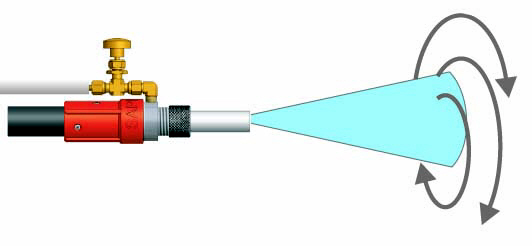

Option 1. Vortex blasting technology

(Especially gentle way to clean)The principle of this blasting is to give rapid rotation to the jet using a special head. The surface is ground by very fine particles at an angle tangentially. Thus, there is obtained abrasive erasing effect which preserves the surface of the object to be cleaned. For this blasting technique there is available a variety of special granulates (glass and stone powder, calcium powder, special powders). Wherever it comes to gentle basting of surfaces, the SAPI vortex technology demonstrates a significant advantage over conventional jet.

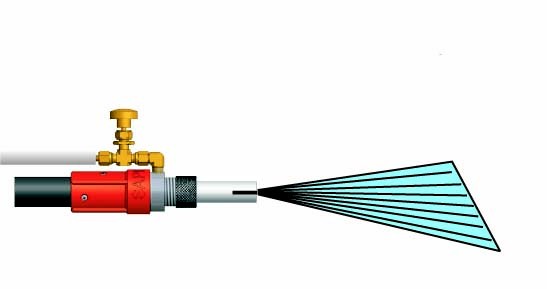

Option 2. Flat-fan blasting technology

(High speed blasting using a flat-fan jet)A special nozzle forms a flat and wide spatula-type jet, which allows to blast large volumes of surface in short time.The width of the jet varies from about 15 to 30 cm depending on the size of the nozzle. The use of different abrasive materials achieves different cleaning results.

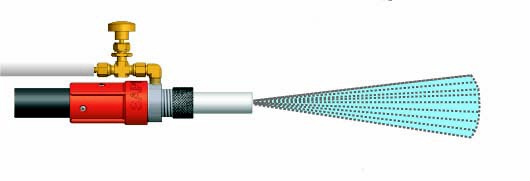

Option 3. Venturi jet (cone) method. Venturi technology

(Classic blasting equipment for all-purpose application)This nozzle accelerates and forms a cone-shaped jet. Abrasive particles hit the surface at a high speed. Due to the high abrasion resistance, this technique is particularly well suited for paint removal and roughening various surfaces (concrete, plaster, etc.).

Examples of SAPI VARIO blasting cleaning equipment use

Cleaning of natural stone, brick, plaster, ceramic surfaces, textured and visible concrete, solid and softwood and other materials.

Removes temporal deposition, wall drawings, organic and mineral paint and many others.

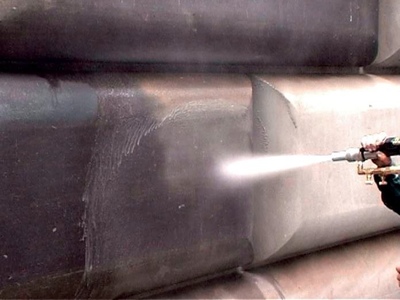

Cleaning of natural stone using a Vortex jet.

Cleaning of monuments, ...

... historic sites and sculptures of temporal depositions....

Removing paint of the walls of the Moscow Kremlin...

…and restoration of the Potemkin Stairs in Odessa.

Cleaning the brickwork..

Cleaning the ceiling beams of temporal layers and mineral depositions.

Removing drawings (graffiti) of the concrete plates, ...

... limestone ...

... and granite stone.