Blasting media

Blasting media should be chosen depending on the task, processing technique and equipment used. The main requirement when choosing blasting media is to obtain the necessary structure and quality of the working surface.

Metallic or mineral, hard or soft, round or faceted blasting media are used; the granule size also plays a significant role. When choosing blasting media, special account must be taken of the following:

- required quality of surface working

- material, shape and thickness of work piece

- applied blasting equipment system

- cost of process for different blasting media, comprising:

- time of working process

- blasting media consumption

- energy consumption of process

- maintenance cost.

Blasting shot and recommendations for its use:

Sand

Allowed only for processing concrete and natural stone.

Pomegranate sand

It is used for processing metal products in an open area.

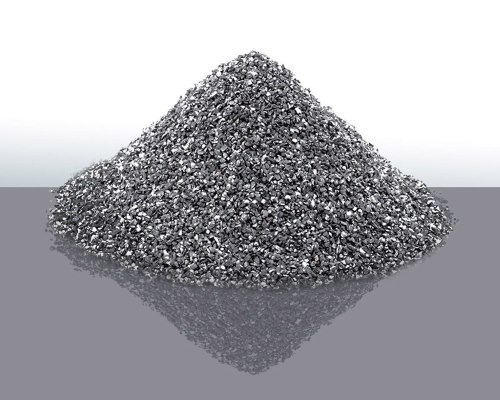

Crushed cast iron

Used for all blasting works. Reusable media for removing oxide scale, rust, various coatings, and deburring.

Chopped steel shot

Used for all blasting works. Reusable media for removing oxide scale, rust, various coatings, and deburring.

Stainless steel chopped shot

For all work with stainless surfaces. Reusable means for removing scale, rust, debris, burrs, etc.

Corundum (Aluminum Oxide)

Used for removing oxide scale, rust, paint, deburring, and matting all metal surfaces. Does not contain metallic inclusions, thus, suitable for processing stainless steel surfaces.

Alundum (White Aluminum Oxide)

Used for processing non-ferrous metals: cleaning, roughening and matting. The surface roughness depends on grain size and blasting pressure.

Slag

Used for removing rust from various surfaces, and also for repair and construction work.

Plastic shot

For finishing the parts, polishing aluminum parts, removing from them defects in casting and smoothing burrs.

Glass beads

Used for finishing delicate surfaces of non-ferrous metals. Do not contain metallic inclusions, thus, suitable for smoothing and cutting down stainless steel surfaces.

Ceramic beads

Used for finishing delicate surfaces of non-ferrous metals. Do not contain metallic inclusions, thus, suitable for smoothing and cutting down stainless steel surfaces.

Фотографии взяты с сайта www.lifeprom.ru